- Depletes human error while sterilizing the air, walls, and surrounding objects without wetting them.

- Sterilizes floating viruses (spatial disinfection) as well as adhesion viruses that are in the smallest and hardest to reach spaces.

- Disinfects efficiently based on the homogeneous spray distribution of our machines to efficaciously disinfect all surfaces.

- 100% coverage to any environment where your typical sprays and wipes cannot reach.

- Our machines can be used around electronic equipment due to our non-wetting capabilities; guaranteed.

- Dry Fog sanitation is a proven method in the food industry to fight against micro-organisms infections.

Understanding Dry Fog and what Bio Sealed’s machines do:

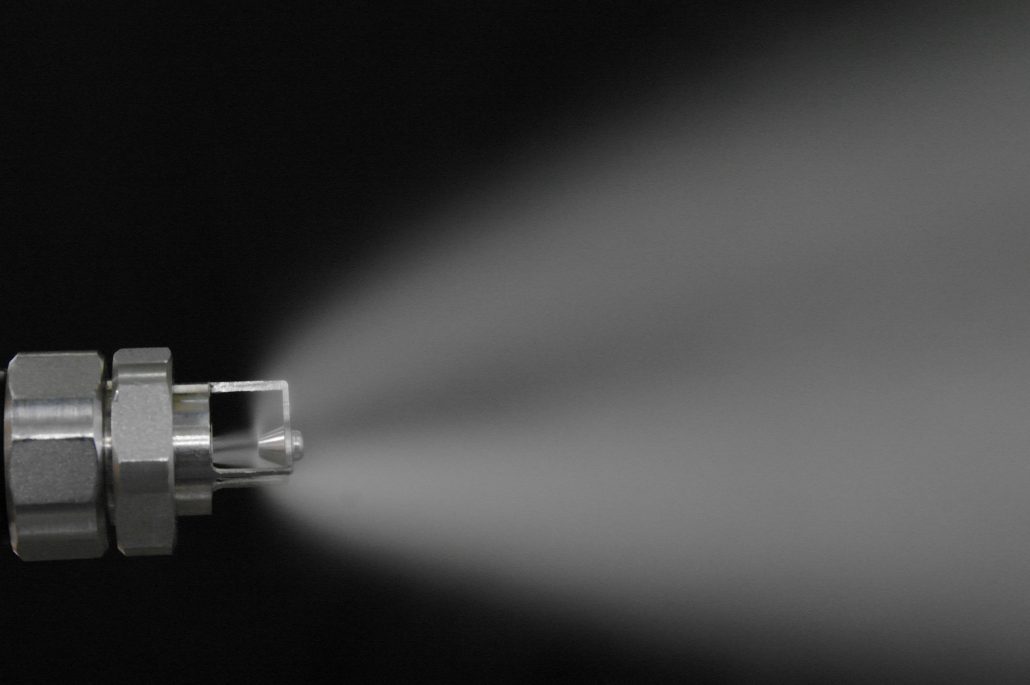

Dry Fog is an ultra-fine fog atomization that has an average droplet size of 7.5 micros (we discuss micron and droplet size below). Due to its size, it is does not wet the environment or the objects it is being dispersed in.

Our machines at Bio Sealed output at a 2.4 to 4.2micron droplet size. Due to its small size, the droplets that are being outputted are evaporating in the air and as they reach a surface, which depletes the ability of wetting.

Our Dry Fog machines use a specific technology that balances air pressure with their patented nozzles to create a uniform fog without dispersing any large droplets. Therefore, we are proven and able to conduct our services in the electronics industry as well as fabrication plants and production facilities with semiconductor systems that have strict humidification requirements.

Understanding how efficient a small droplet is for disinfection efficacy:

The COVID-19 virus is approximately a 0.1 micron droplet that appears in clusters that can measure between a 5-10 micron droplet. At Bio Sealed, our machines are operating on average at a 3.2-micron droplet size which is smaller than the contaminated droplet that is floating in the air.

As our disinfectant CURoxide solution is dispersed into Dry Fog, the water that you have in the droplets evaporates rapidly which leaves the high concentrated Hydrogen Peroxide liquid to get in contact with virus to efficaciously disinfect it (up to a 6-Log reduction).

When the droplets are too big (in similar use to electrostatic spraying), then quickly it becomes corrosive for the environment, human contact, and problematic for electronic systems in the area.

Efficiency of disinfection and droplet size:

Understanding Droplet Size:

The smaller the droplet size, the longer the spray drift. During an application process for sterilization and active treatment, the solution output is broken into spray particles or droplets of various sizes. Managing the size of spray droplets is critical in managing spray drift.

Diameter and Size:

Droplet sizes are measured in microns. A micron is 1/1000 millimeter, or about 1/25,000 of an inch. To get this in perspective, a single human hair is about 100 microns in diameter. Spray droplets smaller than 150 microns tend to be the most prone to drift (Bio Sealed’s machines are outputting at 2.4 to 4.2). These small droplets fall extraordinarily slower than large droplets (that of an electrostatic sprayer). They do not have enough weight to overcome the air resistance to allow them to carry into the smallest of areas.

For further details please visit biosealed.com. This is an introduction to better help understand how Dry Fog works and the importance of droplet size in comparison to sterilization efficacy. Our technology at Bio Sealed is strictly meant to deplete human error while creating the best effectiveness in sterilization and active antimicrobial treatment.